What Are Ledger Board Fasteners?

A ledger board is a horizontal piece of lumber that attaches to the side of your house and serves as the primary anchor for your deck. To keep it firmly in place, you need strong ledger board fasteners like through bolts or structural screws.

These fasteners must resist two main types of force: vertical and lateral. Vertical forces are created by the weight of the deck itself and the loads it carries, such as people, furniture, snow, etc. If overloaded, the ledger connection could shear off the wall and cause the deck to drop to the ground. Lateral forces occur from the movement of people on deck, seismic activity, or wind loads. These forces can push the deck side to side or front to back, and if the ledger is not properly secured, cause it to pull away and separate from the house.

Ledger board failure is one of the leading causes of deck collapse. Inadequate fasteners or improper fastener placement are major contributors. By the end of this guide, you will understand the advantages and disadvantages of each type of fastener and cover the installation basics to help you create a rock-solid ledger connection that lasts for decades.

Ledger Bolts or Screws, which is Best?

Through bolts provide the greatest holding power, but they can be more difficult to install. Lag screws (often called lag bolts) and structural ledger screws are easier to work with and can still create a safe, long-lasting connection. Whichever fastener you choose, make sure it’s approved for use with pressure-treated lumber, since the chemicals used in treated wood can be highly corrosive. Also, keep in mind that building codes can vary from one municipality to another, so it’s essential to check with your local building official during the planning stage of your deck. Keep reading to learn more about the strengths and limitations of bolts and screws.

What Are Through Bolts?

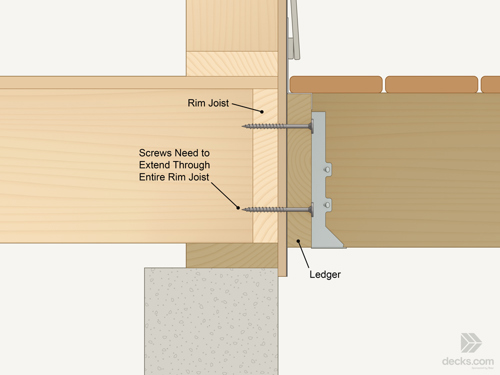

Through bolts are heavy-duty fasteners that pass completely through the ledger board, sheathing, and rim joist. They are secured inside the home by tightening a nut, which acts as a clamp that pulls all the materials tightly together. Installation is straightforward: drill a hole through both the ledger and rim joist, insert the bolt, and tighten it from the inside with a nut. Keep in mind that two washers are typically required—one under the bolt head and one under the nut. Because each nut must be tightened from inside the house, you’ll need access to every bolt location, which can mean cutting into finished surfaces to reach the interior framing.

Advantages of Through Bolts

- Through bolts are extremely strong and provide the best resistance against both vertical and lateral forces.

- They require fewer fasteners than screws.

- They are less affected by vibration, seasonal wood movement, and environmental changes, which can loosen screws over time.

Disadvantages of Through Bolts

- Through bolts require predrilled holes.

- Bolt locations must be spaced to avoid both the interior floor joists and the exterior deck joists.

- Installation takes more time and is difficult to do alone.

- Each bolt requires two washers and one nut, which means more components to buy and keep track of.

- If there is no access to the interior framing, cutting into finished surfaces at every fastener location may be required.

What are Structural Screws?

For decades, the lag screw (often called a lag bolt because of its bolt-like head) was the standard alternative to using bolts. However, since the early 2000s, structural ledger screws have become the preferred choice. They are typically less expensive, and many brands feature a flush head that will not interfere with joist placement. Unlike lag screws, structural screws have a narrow shank and a cutting tip that drills as it drives, eliminating the need for a predrilled hole.

The case for structural screws over lags is even stronger with the release of the 2024 International Residential Code. Lag screws now require two different predrilled holes: a smaller pilot hole through the rim joist so the threads can bite securely without splitting the wood, and a larger clearance hole through the ledger and sheathing so the materials can be clamped tightly together without binding or creating a gap. One thing to note is even structural screws require predrilled holes for those fasteners placed nearest the very end of a ledger board, where the wood splits easier. The exact hole size will depend on the width of the screw shank and the recommendation from the manufacturer.

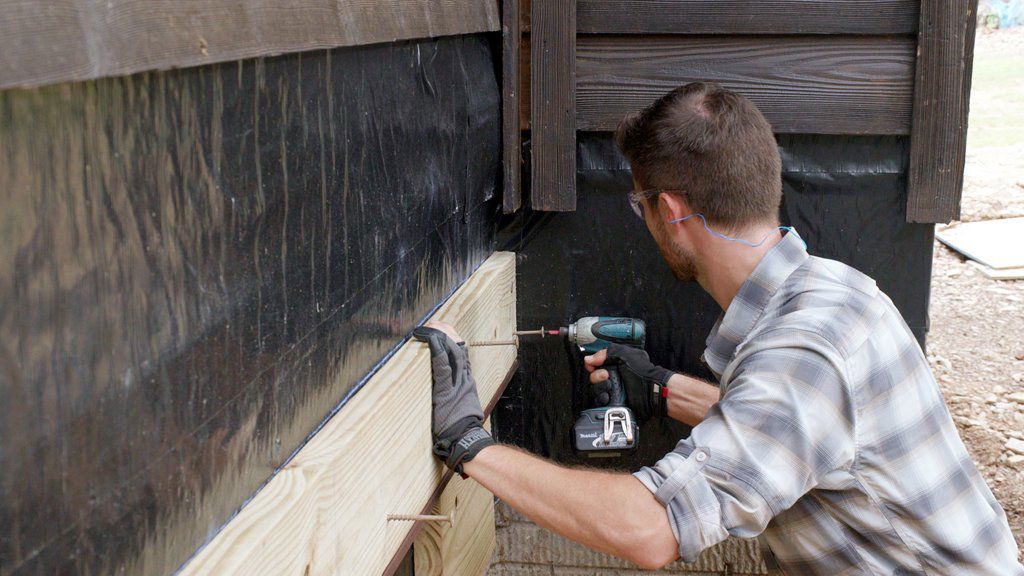

One of the biggest advantages of structural screws over bolts is convenience. If you are working on a home with a finished basement, and the deck ledger attaches to the rim joist at the first floor, you can install screws without cutting large access holes in the finished ceiling at every screw location. However, be aware that some inspectors may require one or two small openings, so they can verify that the screws penetrate completely through the rim joist, which is a building code requirement.

Advantages of Structural Screws

- Structural screws are easier to install than through bolts.

- They reduce or eliminate the need for access to the inside framing.

- Many structural screws have flush heads that will not interfere with joist locations.

- They are generally more cost-effective than bolts.

Disadvantages of Structural Screws

- Without interior access, you cannot always confirm that every screw is anchored into solid, sound wood.

- Gaps between the ledger, sheathing and rim joist are harder to detect and eliminate when using screws.

- Structural screws require more fasteners to carry the same load as bolts.

How long do Ledger Fasteners Need to Be?

Ledger through bolts need to be long enough so that two or three threads are visible past the fully tightened nut, usually about 1/4 inch. When using lag or structural screws, the tip of the screw should fully penetrate and protrude past the face of the interior side of the rim joist—1/4 inch is more than enough. This ensures maximum penetration into the rim joist and provides a visual confirmation that the screw is fully seated. To ensure the fasteners you are using are long enough, you need to know:

- Thickness of the ledger board

- Thickness of the sheathing

- Thickness of the rim joist

- Combined thickness of the washers and nut (*if applicable)

Once you know the size of all these components, the math is easy:

a+b+c+*d+1/4” = The minimum required length of the fastener. Because ledger fasteners are usually available in 1/2-inch to 1-inch increments, it’s unlikely you will find a fastener that will be exactly the length you need, so once you determine the minimum length, just choose the next larger size.

How Many Ledger Fasteners Are Required?

The number of fasteners you need to safely secure a deck ledger depends on several factors. While you can always add more for peace of mind, code requirements are based on the type of fastener and the conditions your deck must withstand. Key considerations include:

- Live Load is the weight your deck needs to carry, including people, furniture, etc. Minimum deck capacity is typically 40 psi. However, if you add something heavy, like a hot tub, or live in an area prone to heavy snowfall, additional fasteners will be required.

- Ledger Materials vary, and each type of wood has different physical properties. Some structural screw manufacturers adjust the required number of fasteners based on the wood species.

- Rim Joist Material type affects the way that screw threads hold. Threads tend to hold better in engineered wood than in natural wood, because the density is more uniform compared to natural lumber, which has softer and harder grain sections.

- Span of the Joists affects how much weight is transferred to the ledger board. The longer your joists span, the greater the weight transferred to the ledger. More span means more load, which in turn requires more fasteners to safely carry the deck’s weight.

Where Should the Ledger Fasteners Be Placed?

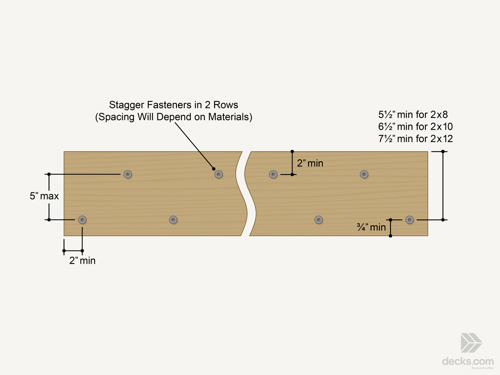

Per the 2024 IRC (International Residential Code), place ledger fasteners in two staggered rows, not stacked. Keep holes at least 2 inches down from the top edge, 3/4 inches up from the bottom edge and 2 inches in from the ends. You will need to maintain a minimum distance of 1-5/8 inches and maximum distance of 5 inches between the two rows. When using structural screws, always be sure to follow the manufacturer’s spacing instructions rather than the code requirements.

The Rim Joist Size Can Also Affect Ledger Fastener Spacing!

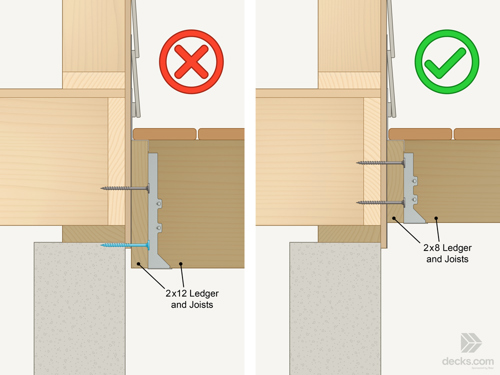

A home’s rim joist also shares many of the same spacing requirements as a ledger board. This is not a problem when attaching a 2x12 ledger to a 2x12 rim joist where both boards line up vertically. However, when building a deck in areas that receive heavy rainfall or a lot of snow, it’s a good idea to step down the ledger board so the top surface of the decking is down several inches from the bottom of the door opening. A step helps protect the vulnerable door sill area from splashing rain or standing snow. Figure One illustrates how dropping a ledger can make following spacing requirements impossible. This is one of the most common causes of confusion and can lead to deck structural failures if not addressed.

One way to deal with step-downs is to build the deck with a smaller ledger and smaller joists, as shown in Figure Two. Smaller joists won’t be able to span the same distance, which may require you to add an additional support beam under the joists. The only other method is to have an engineer design a specific ledger fastening plan for your deck or build a freestanding deck. Speak with your local building official first to see if they can provide a simpler solution.

Is It Okay to Connect a Ledger Board to Studs?

No, the IRC does not allow attaching a deck ledger directly to wall studs; ledgers must be fastened to a band or rim joist that transfers loads into the floor framing. Attaching a ledger to studs concentrates loads on a few narrow framing members instead of distributing them, which risks structural failure. Since the code only provides prescriptive details for rim joist connections, any attempt to attach a ledger to studs would require a structural engineer’s design. Otherwise, the recommended alternative is to build a freestanding deck.

Can a Ledger Be Attached to a Concrete Wall?

Yes and no. Yes, a ledger can be attached to solid concrete walls when fastened with code-approved fasteners like sleeve anchors and concrete screws, but hollow concrete block walls are not permitted under the prescriptive IRC provisions. The problem is that block walls have hollow cores, so fasteners don’t get the embedment or pull-out resistance needed to transfer deck loads safely. If you need to connect to a block wall, it generally requires filling the block cores with concrete, which isn’t an option on an existing house.

Courtesy of Simpson Strong-Tie

Can a Ledger be Attached to a Brick Wall?

No, attaching a ledger directly to brick is not allowed. Most exterior brick walls are simply a veneer or type of cladding and not designed to carry the weight of a deck. In many cases, a safer and simpler alternative is to build a freestanding deck that doesn’t rely on the house wall for support. This avoids the risk of compromising the brick veneer and ensures the deck has its own stable, code-compliant foundation.

If adding posts and beams near the house interferes with windows or door openings, there are products available that allow a ledger to be installed on the surface of the brick. But this requires specialty fasteners, such as Simpson Strong-Tie’s BVLZ Brick Veneer Ledger Connectors, that are engineered to transfer loads back through the veneer and into the structural framing behind it.

Can You Attach a Ledger to Floor Trusses?

The answer is complicated. Many floor truss systems use a narrow ribbon board at the end of the trusses instead of a rim board. The International Residential Code (IRC) does not provide prescriptive guidance for attaching a deck ledger to floor trusses. It’s essential to follow the truss manufacturer’s recommendations for proper fastening methods. Some designs may require additional blocking to safely transfer loads—a step that is far easier to complete during the original construction of the house rather than as a retrofit.

Learn More About Installing a Ledger Board

Choosing the right fasteners and understanding how ledgers attach to different framing conditions are critical steps in building a safe, long-lasting deck. For a detailed walk-through, including flashing installation, check out How to Install a Deck Ledger Board and Attach Flashing on Trex Academy.

Rather Work with a Pro?

Attaching a ledger board isn’t just another step in the process—it’s the most critical and technically demanding part of building a deck. It requires accurate layout, precise fastening, and a clear understanding of wall assemblies, cladding and building codes. Hiring a professional can ensure your ledger connection, framing, decking and railing all meet code and stand the test of time. To find an experienced contractor, explore the TrexPro® network